Shake flask experiments represent an ideal set-up for many purposes and allow the testing of different conditions in lower volumes. Therefore, costs of medium and additives are generally low, and experiments can be set-up in places with limited space.

In some established fermentations, however, the timepoint comes when it will be necessary to scale up culture volume to increase product titers. This upscaling raises certain challenges that must be addressed to secure a smooth transference of the bioprocess from flasks to bioreactor. Here, we cover the 5 main factors that you should consider during upscaling.

1. Make Sure Your Cells Can Breathe.

Many bioprocesses are aerobic, meaning they use organisms that are dependent on oxygen for metabolic activity and growth. Thus, when scaling up your aerobic cultures from shake flasks to significantly higher volumes in bioreactors, enabling a sufficient oxygen supply is important and at the same time challenging.

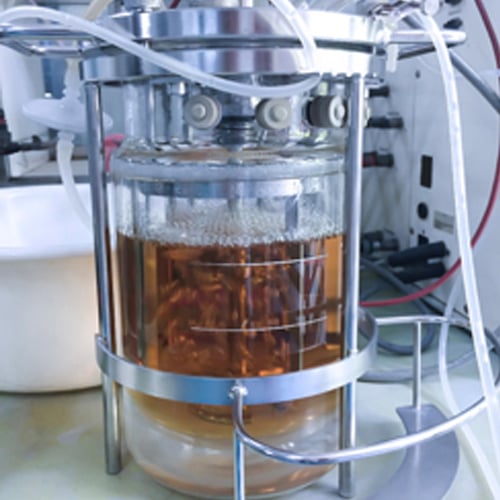

In shake flask experiments, shaking increases the exposure of the medium to oxygen in the surrounding air, easily providing a sufficient level of dissolved oxygen. In stirred bioreactors, air or pure oxygen must be introduced to the culture, usually from compressed air cylinders. Spargers distribute the gas more evenly throughout the culture, allowing a higher gas/medium interface for a higher oxygen concentration in the medium.

OXYGEN TRANSFER RATE:

The oxygen transfer rate (OTR) describes the transfer of oxygen from the gaseous phase into the culture medium. It is influenced by many factors, like the design of the impeller, agitation speed, gas flow rate, oxygen concentration in the gaseous phase, and the volume of the bioreactor.

Usually, the oxygen concentration is measured by specialized sensors and kept at a desired setpoint, controlled by the bioprocess software. If the oxygen level drops, the software would initiate certain steps successively to increase it, e.g., it would start with accelerating the agitation speed, when not sufficient increase the gas flow rate and possibly, as a last measure, rise the oxygen concentration in the gas mixture.

Depending on the organism and the design of the bioreactor, your parameters should be adjusted accordingly, ensuring the ideal oxygen supply for your specific bioprocess.

2. Think Twice: Which Bioreactor and Stirring Setup is Right for Your Bioprocess?

When a culture is taken from a petri-dish to a shake flask or from a shake flask to a small-scale bioreactor, the environmental conditions of the culture change significantly. In these steps, changes in the cellular metabolism and therefore in product titers or product quality are often seen. When moving from benchtop bioreactors to pilot bioreactors used in production, which can handle thousands of liters, bioprocesses are generally more stable. However, higher volumes are often more difficult to control, e.g., in term of oxygen supply, and necessitate high medium and nutrient quantities which increase the cost of the bioprocess. The right size of the bioreactor should therefore be chosen carefully.

Besides stainless steel bioreactors, single-use systems exist. The first-time application ensures that there was no contact with any other cells before, which reduces the risk to cross-contaminations. Therefore, these systems are practical for pharma or food industries and often used for bioprocesses with mammalian cells. However, for cells with a high oxygen demand, these vessels are not suitable as a reduced OTR is usually achieved.

In a shake flask experiment the culture is mixed by shaking, whereas in bioreactors mixing is achieved by stirring. Stirring enables a regular distribution of nutrients throughout the fermentation broth, prevents cells from settling, and ensures a good oxygen supply. It uses a different agitation mode and therefore influences the fluid dynamics in a way dissimilar from shaking. Choosing the right stirring equipment and speed is crucial for successful bioprocesses.

Depending on your organism, a Rushton-type flat-bladed impeller might be the right choice. It easily reaches high agitation speeds and is commonly used for bacteria or yeast cultures which are less sensitive but require higher OTRs. However, certain organisms like eukaryotic cell lines are more susceptible to shear stress and will benefit from an impeller with pitched blades and a slower agitation speed.

3. Consistency is Key – Keeping Your Parameters Within Range Will Positively Affect Your Bioprocess.

A clear advantage of bioprocessing in bioreactors is the fact that parameters are tightly monitored, and mostly automated responses are implemented (e.g., a higher stirring speed when the oxygen level drops). Keeping parameters like temperature, oxygen concentration, or pH constant during the process and throughout the medium is crucial for controlled fermentations. The culture volume plays a role in these efforts. For example, in larger volumes, a higher stirring speed must be applied to reach the same mixing speed compared to lower volumes, where the same mixing requires less energy.

Because bioreactors usually offer different feeding options, pH can conveniently be controlled by the feeding of acids and bases. To keep the temperature constant, the heat produced from exothermal process reactions must be removed. This is achieved by using a thermal jacket, wrapped around the vessel, which is designed to heat or cool the system. Importantly, also stirring and aeration introduce extra heat into the system which must be considered if these processes are accelerated.

Furthermore, faster stirring can induce increased foam building which negatively influences the consistency of the process due to e.g., cell stripping. Mechanical (influencing the fluid dynamics) and chemical (anti-foam) measures exist, to reduce foam formation. Note that the addition of anti-foam, in turn, can further affect your process or product.

Finally, to keep parameters constant across scales, it is recommendable to use similar equipment and strategies during these steps, e.g., use the same impeller design, the same feeding strategy, or aeration concept.

4. Invited Guests Only: Reduce the Risk of Contamination.

Large scale fermentations require a high quantity of medium, supplements, and cells as well as substantial efforts in setup and operation. The consequences of a process failure are therefore much more severe than in small scale shake flask experiments. Certainly, the risk of contaminations must be minimized to avoid such negative outcomes and sterile conditions should be assured at all times. Fortunately, automated processes in bioreactors require fewer manual steps, e.g., sampling. However, pre-cultures need to be grown and harvested in multiple steps.

The higher the final volume, the more pre-culture steps are usually required to sequentially increase the cell density suitable for the desired volume. In each step, the purity of the culture should be checked and assured. Similarly, all substances, including gases, that are introduced during the process must be sterilized and must only enter through sterile filters that should be regularly checked and replaced, to avoid membrane fouling.

After each fermentation, the vessel needs to be thoroughly cleaned to avoid cross-contamination of products. If single-use vessels are employed, this step is redundant and a clean, sterile environment for the process is easily assured. However, this solution is not applicable for many fermentations, especially processes involving high cell densities. For sterilizing the vessel and medium for the next process, different methods exist, including autoclaving the fresh medium in the tank or cleaning the tank with germ-killing agents and introducing fresh media through filters.

5. Happy Cells are Good Cells – Factor in Your Organisms’ Metabolic Requirements.

Different organisms, or even different subtypes of the same organism, represent a large variety of metabolic profiles. Naturally, these profiles influence, and are influenced by, the bioprocess and must be considered during each fermentation and the upscaling process.

Even though, these characteristics are not necessarily scale-dependent, the cell environment changes throughout scales. More significantly when moved from shake flasks to bioreactors but also, to some extent, between a smaller, usually well-mixed reactor and a bigger one. These changes may in turn cause metabolic adaptations that might influence your process. A thorough understanding of your organism and its metabolic requirements is therefore an important requisite for upscaling, to avoid unpleasant surprises.

Automated feeding strategies are easily accessible in bioreactors. Which feeding strategy is right for your process should be carefully evaluated. If the metabolic flux of your organism is slow, a batch fermentation might be a good fit. With fast-growing organisms, a continuous or fed-batch feeding of sugar or substrate might be beneficial, also depending on the effect that higher substrate concentrations might have on biomass or product formation. Furthermore, it plays a role which type of metabolite your product represents; primary metabolites are produced simultaneously with biomass production whereas secondary metabolites are formed after growth has stopped. Feeding strategies can be adapted accordingly.

Not sure which vessel type and biomass monitoring technique are the best fit for your bioprocess?