What is Optical Density (OD600)?

Optical density to measure biomass is a well-known, long time practiced offline technique, used, and described in many publications.

- Optical Density (OD) Measurements

Oldie but Goodie

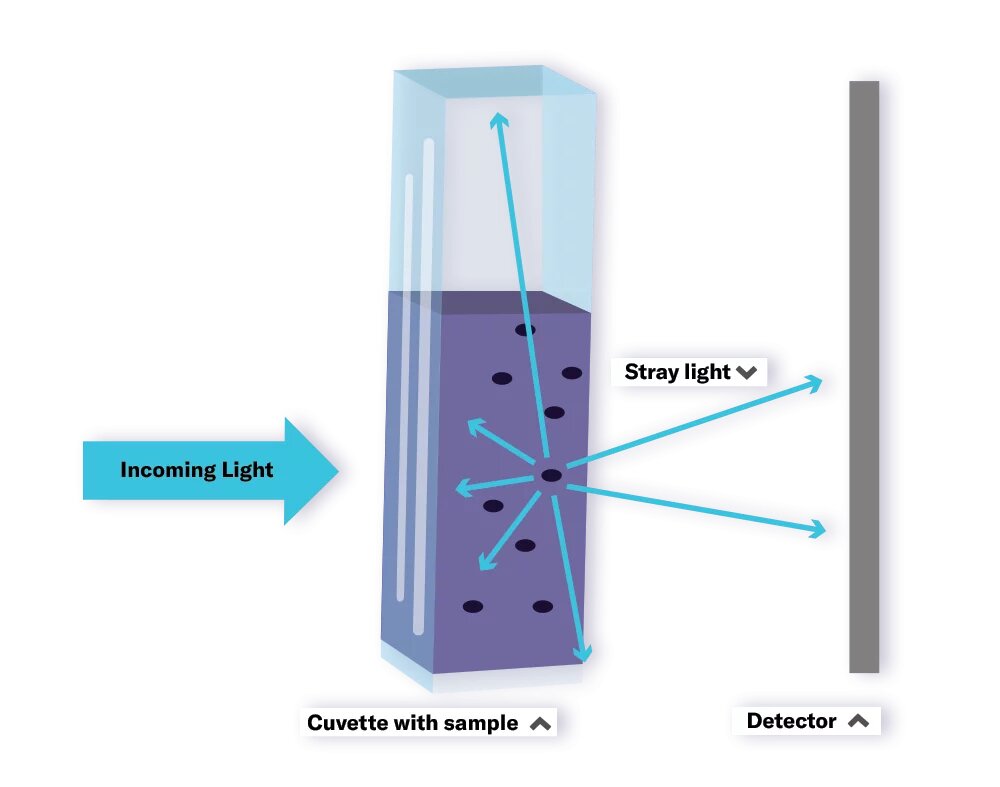

Principle of Measurement: Absorbance

Light with a specific wavelength is emitted into the fermentation broth. A sensor on the other side of the broth detects the intensity of the light as it passes through. The more cells in the culture, the less light. Using the Lambert Beer law, this signal can be used to calculate the optical density, or OD.

Technologies:

Used in photometers combined with offline sampling, in plate readers, or in invasive probes for bioreactors.

-

Advantages

- Very sensitive – can measure very low biomass concentration (usually <0.1 OD).

- High reproducibility.

- Easy to use.

- Established technology with plenty of reference data.

- Often fairly low investment costs (CAPEX) since the equipment needed already exists as standard lab infrastructure.

-

Disadvantages

- Offline and and often invasive. Samples need to be taken, which risks contamination, interrupts the bioprocess and wastes culture volume.

- For biomass concentrations above 0.8-1 the sample has to be diluted (adding additional manual work).

- Discontinuous data.

- Low data density (e.g., no data from the night or the weekends).

- Particles can influence measurements.

- Does not work with filamentous organisms and barely works with anaerobics.

- Running costs for cuvettes and personnel (OPEX).

- Requires a certain minimal culture volume to ensure enough data points.

Optical Density (OD) Measurements

Oldie but Goodie

Principle of Measurement: Absorbance

Light with a specific wavelength is emitted into the fermentation broth. A sensor on the other side of the broth detects the intensity of the light as it passes through. The more cells in the culture, the less light. Using the Lambert Beer law, this signal can be used to calculate the optical density, or OD.

Technologies:

Used in photometers combined with offline sampling, in plate readers, or in invasive probes for bioreactors.

-

Advantages

- Very sensitive – can measure very low biomass concentration (usually <0.1 OD).

- High reproducibility.

- Easy to use.

- Established technology with plenty of reference data.

- Often fairly low investment costs (CAPEX) since the equipment needed already exists as standard lab infrastructure.

-

Disadvantages

- Offline and and often invasive. Samples need to be taken, which risks contamination, interrupts the bioprocess and wastes culture volume.

- For biomass concentrations above 0.8-1 the sample has to be diluted (adding additional manual work).

- Discontinuous data.

- Low data density (e.g., no data from the night or the weekends).

- Particles can influence measurements.

- Does not work with filamentous organisms and barely works with anaerobics.

- Running costs for cuvettes and personnel (OPEX).

- Requires a certain minimal culture volume to ensure enough data points.

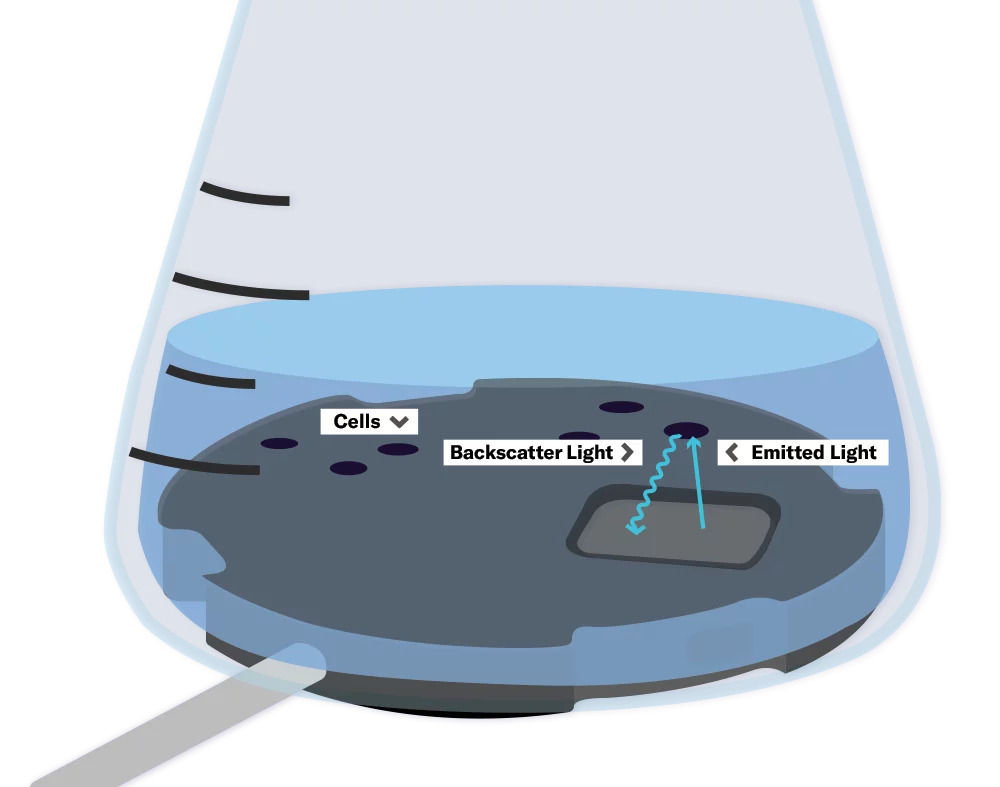

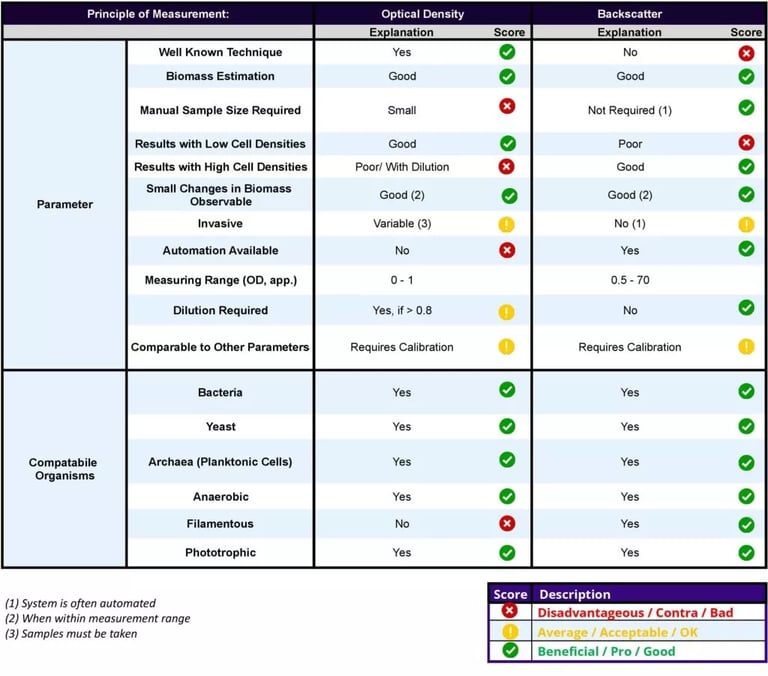

What is Backscatter Light?

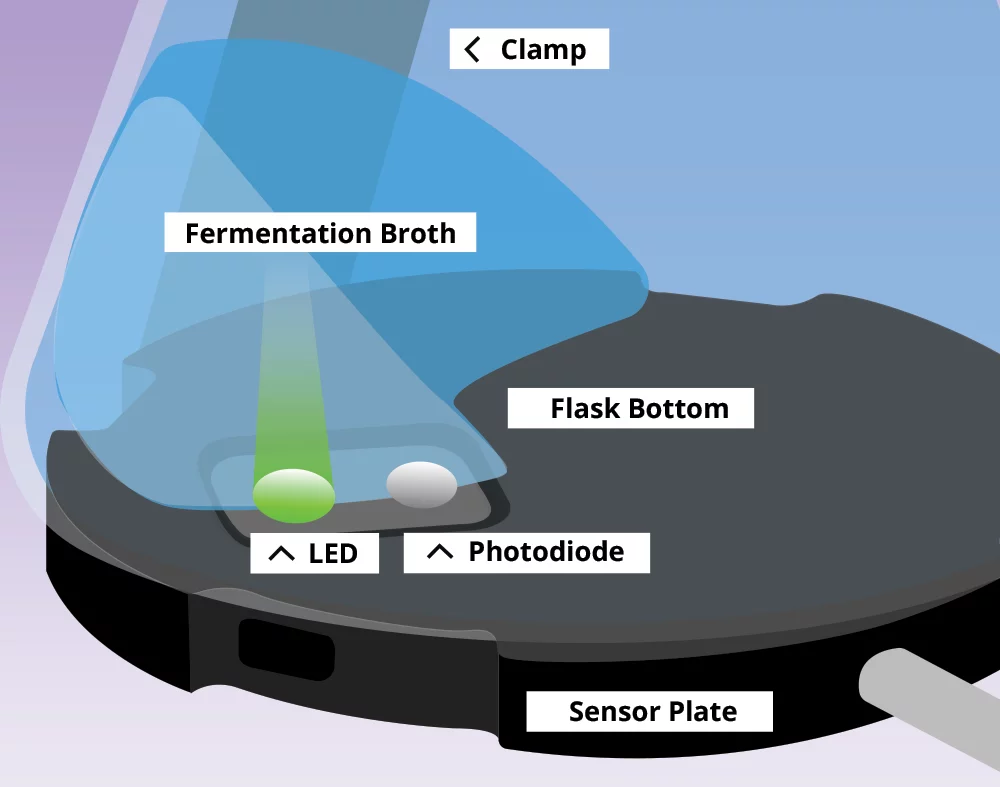

A newer, more modern approach to biomass monitoring is backscatter. Like OD, backscatter uses a device that contains both a light source and a light detector. In contrast, however, both the source and sensor are located on the same side of the sample.

MODERN APPROACH, FAST-GROWING TREND

Principle of Measurement: Backscatter

Light with a specific wavelength is emitted into the fermentation broth. A sensor close to the light source detects the amount of the light scattered back by the cells and other particles in the broth. The more cells in the culture, the more light is scattered back.

Technologies:

Used in non-invasive sensors for shake flasks and bioreactors, and in invasive probes for bioreactors.

-

Advantages

- Automated (measurement and data handling).

- Online and non-invasive (no samples need to be taken).

- Good measurement range without the need for dilutions.

- No running costs (OPEX).

- Continuous real-time data.

- High resolution.

- Easy to use.

- Works with filamentous and anaerobic organisms.

- Applicability to a broad variety of vessel types (μL to L scale).

-

Disadvantages

- Lower sensitivity than OD measurements.

- Absolute values may differ due to flask-to-flask differences or experimental set-up. Only relative values can be compared directly and without calibration.

- Scientifically proven method with reference data, but not yet as established as OD measurements.

- Particles can influence the measurement.

- Medium investment costs (CAPEX) for sensors and software.

Backscatter Measurements

MODERN APPROACH, FAST-GROWING TREND

Principle of Measurement: Backscatter

Light with a specific wavelength is emitted into the fermentation broth. A sensor close to the light source detects the amount of the light scattered back by the cells and other particles in the broth. The more cells in the culture, the more light is scattered back.

Technologies:

Used in non-invasive sensors for shake flasks and bioreactors, and in invasive probes for bioreactors.

-

Advantages

- Automated (measurement and data handling).

- Online and non-invasive (no samples need to be taken).

- Good measurement range without the need for dilutions.

- No running costs (OPEX).

- Continuous real-time data.

- High resolution.

- Easy to use.

- Works with filamentous and anaerobic organisms.

- Applicability to a broad variety of vessel types (μL to L scale).

-

Disadvantages

- Lower sensitivity than OD measurements.

- Absolute values may differ due to flask-to-flask differences or experimental set-up. Only relative values can be compared directly and without calibration.

- Scientifically proven method with reference data, but not yet as established as OD measurements.

- Particles can influence the measurement.

- Medium investment costs (CAPEX) for sensors and software.

DOWNLOAD THE FULL BIOMASS MONITORING COMPARISON GUIDE

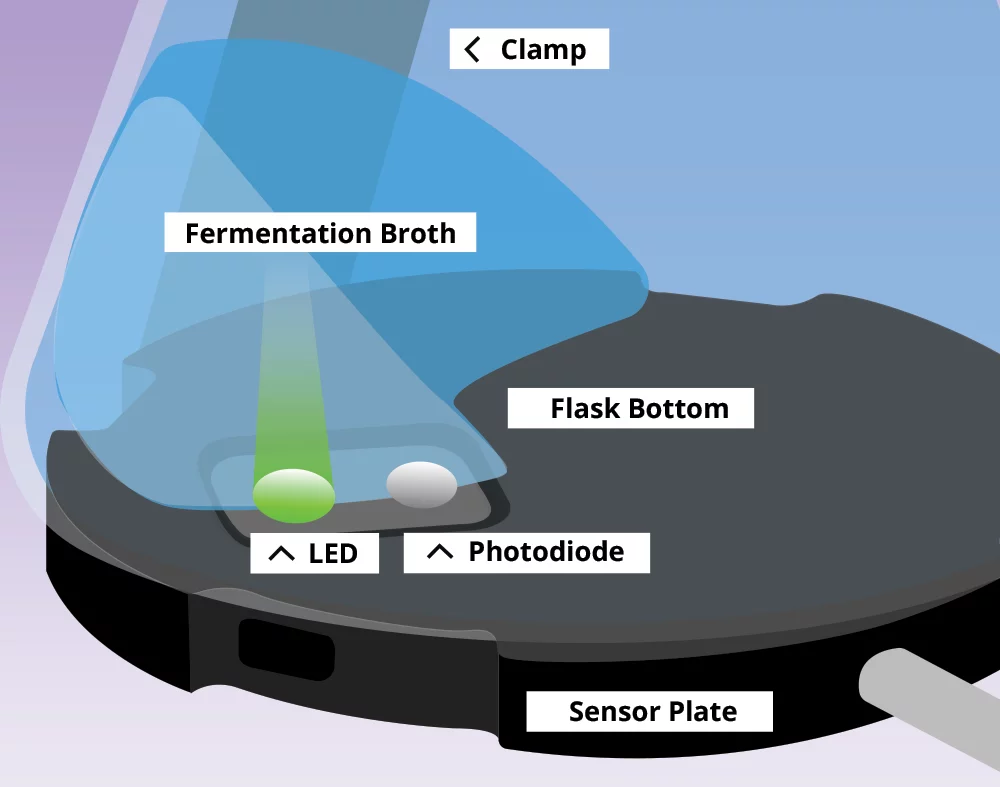

See It in Action

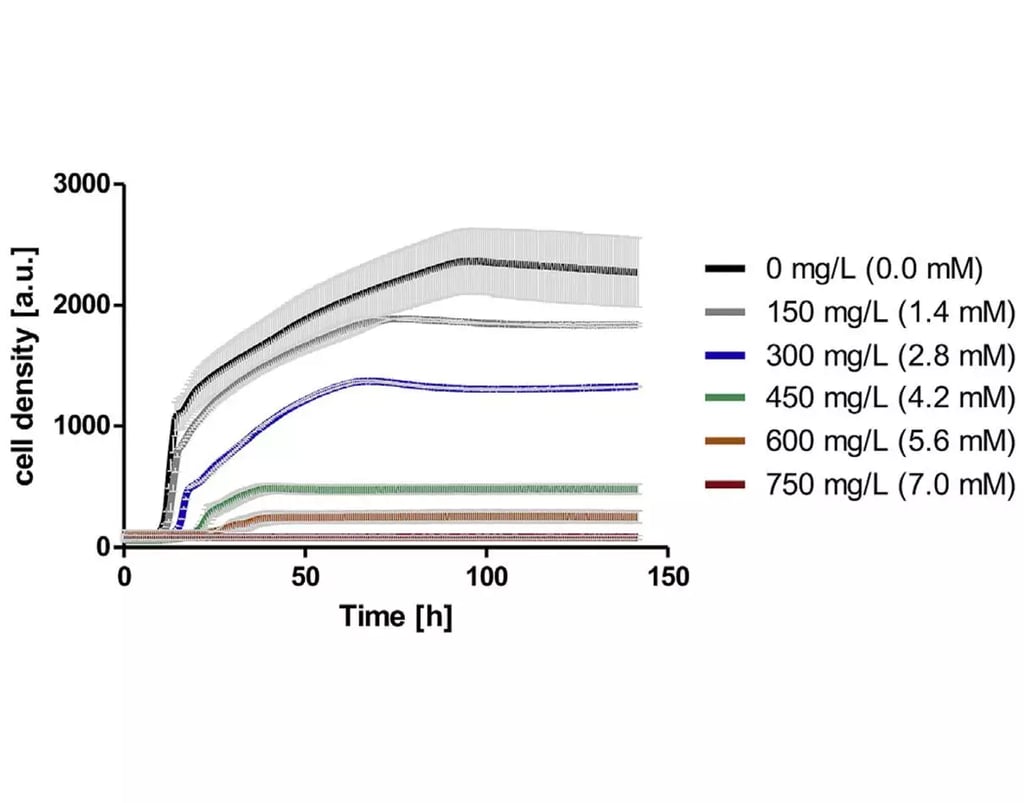

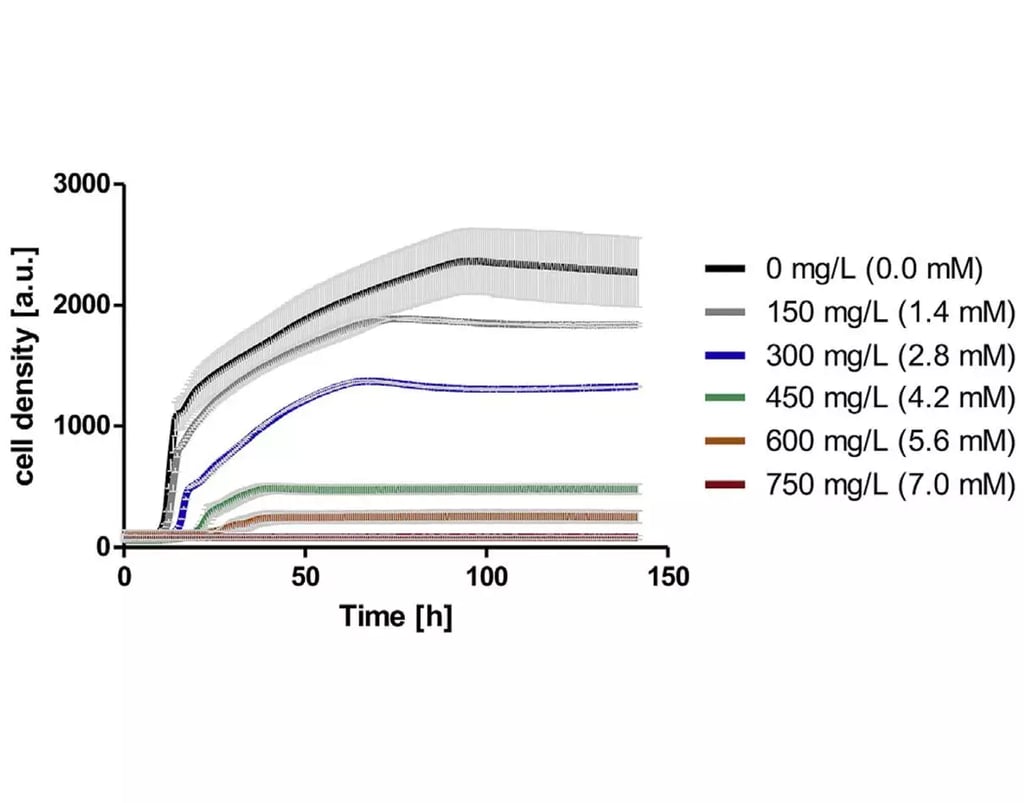

The Cell Growth Quantifier (CGQ) is SBI’s solution to biomass monitoring in shake flasks and other vessels. This optical sensor-based technology uses backscattering light to monitor biomass and growth rates, producing high-resolution growth curves of each culture. Dr. Julia Hitschler from The University of Frankfurt has been using the Cell Growth Quantifier (CGQ) with her team for the last five years. They often use the device for screenings and for toxicity tests. Using the CGQ, they were able to see the effect of different m-cresol concentrations on the growth of S. cerevisiae CEN.PK2–1C “with high resolution and without any time-consuming manual sampling required for offline OD growth curves.”

View The Full Story

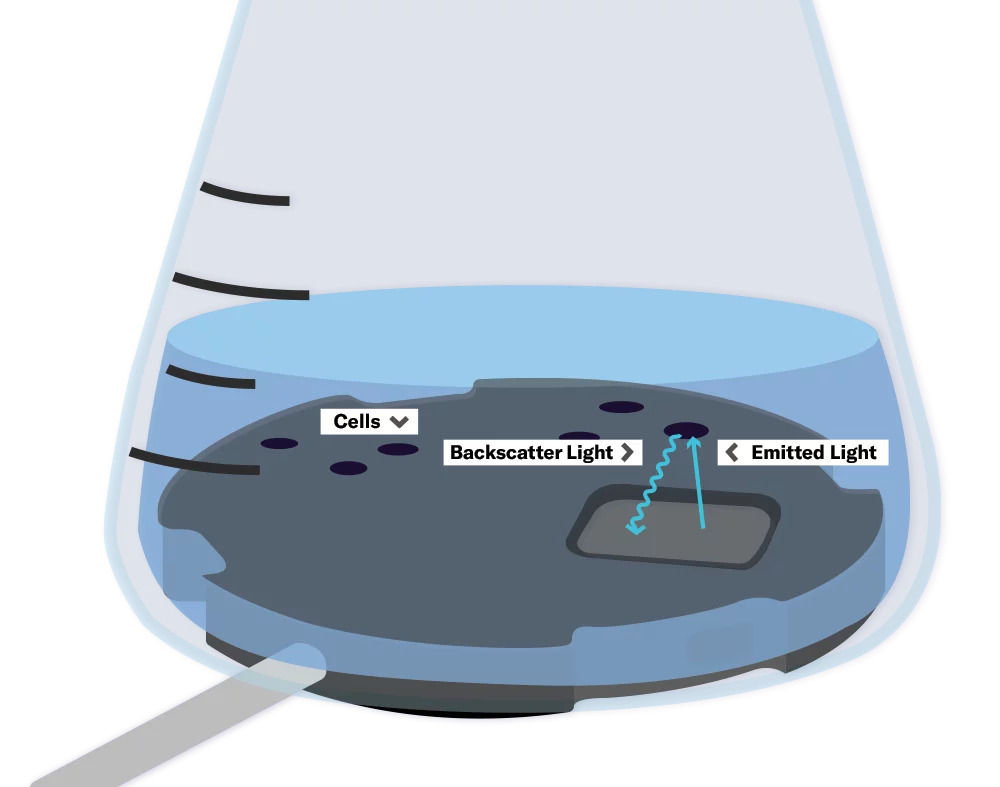

Conclusion

Both OD and backscatter measurements can be used to successfully measure biomass in cell cultures. While many are most familiar with optical density, backscatter is the up-and-coming trend in biomass monitoring. Each method has pros and cons and knowing these points can make all the difference for your application.