Customer Success Story

Using The CGQ Bior To Monitor K. Marxianus During The Production Of Ethyl Acetate

Customer

Dipl.-Ing. Andreas Hoffmann, Bioprocess Engineering group (Prof. Dr.-Ing. Thomas Walther), Dresden University of Technology (TU Dresden)

Background

Ethyl acetate (EA) has great industrial relevance, but the process to obtain EA relies on petroleum feedstocks and multiple-unit operations. The biosynthesis from renewable raw material by yeasts like Kluyveromyces marxianus is an attractive alternative.

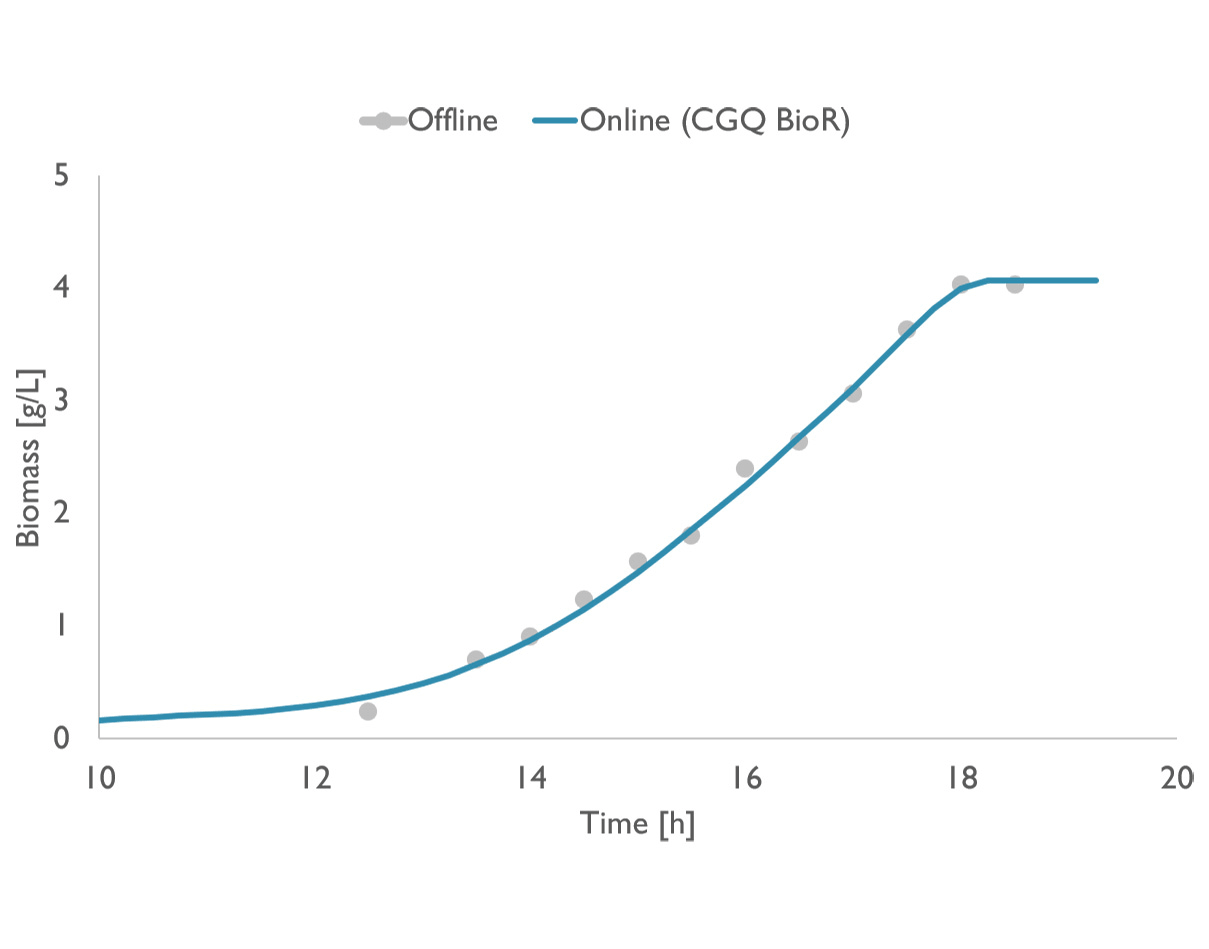

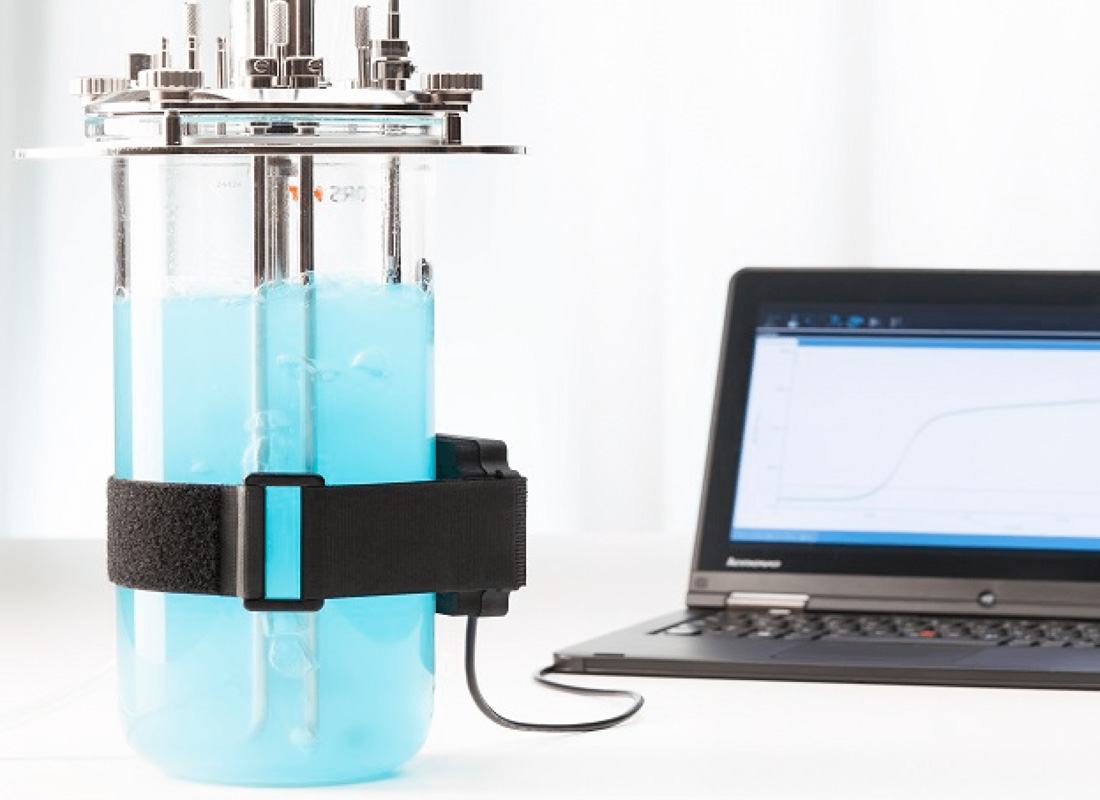

In this experiment, K. marxianus DSM 5422 was cultivated in a synthetic medium without iron, as iron limitation induces the synthesis of EA. However, due to contamination of media components, some iron always is available and thus enables a certain biomass growth. In this case, when the iron from the medium is consumed and the intracellular iron is completely used up, the growth rate decreases and EA is produced. The reduction of the growth rate could be observed by the online backscatter signal measured by the CGQ BioR which correlated nicely with the offline cell dry weight. Additionally, the EA concentration was determined via the exhaust gas and therefore it was possible to monitor the whole cultivation with a very high resolution. In conjunction with the CGQ BioR, biomass-specific EA synthesis rates could be calculated very easily. By doing so, optimal production stages can be identified and this knowledge is then used for process optimization.

Fig. 1 Growth curves of K. marxianus DSM 5422. Online Biomass data was generated with aquila biolabs’ Cell Growth Quantifier for bioreactors (CGQ BioR). Cultivation conditions: synthetic medium, 32°C, 1500 rpm, gas flow rate 2 L/min, total volume 2 L.

Fig. 1 Growth curves of K. marxianus DSM 5422. Online Biomass data was generated with aquila biolabs’ Cell Growth Quantifier for bioreactors (CGQ BioR). Cultivation conditions: synthetic medium, 32°C, 1500 rpm, gas flow rate 2 L/min, total volume 2 L.

Testimonial

“The Cell Growth Quantifier for bioreactors (CGQ BioR) allowed us to obtain biomass data of our yeast Kluyveromyces marxianus in real time without any manual sampling. The device exhibited high signal resolution and smoothness accompanied by low background noise and signal drift. In conjunction with the CGQ BioR, the biomass-specific EA synthesis rates were easily calculated. In addition, the automated CGQ BioR system provides precise growth curves with a very dense sampling interval, freeing my time for tasks with higher added value. Finally, the CGQ BioR reduced the possibility of contamination because it is a non-invasive technology, which is very important in a long experiment like those normally made in bioreactors.”

Dipl.-Ing. Andreas Hoffmann (PhD student)