Dissolved Oxygen Monitoring in Baffled Shake Flasks

Reliable oxygen measurements, even under baffled conditions, for improved bioprocess development.

The DOTS Platform

Build a Smarter Shake Flask, One Parameter at a Time

.png)

Sensing & Controlling

Monitor critical process parameters like DO and biomass and add fed-batch capabilities to your shake flask.

Data Transfer

Data is transferred from our shake flask sensors to the DOTS Software via wired connection.

Sensor Handling & Data Monitoring

Use our cutting edge DOTS Software to gain access to actionable insights and control of your shake flask bioprocesses.

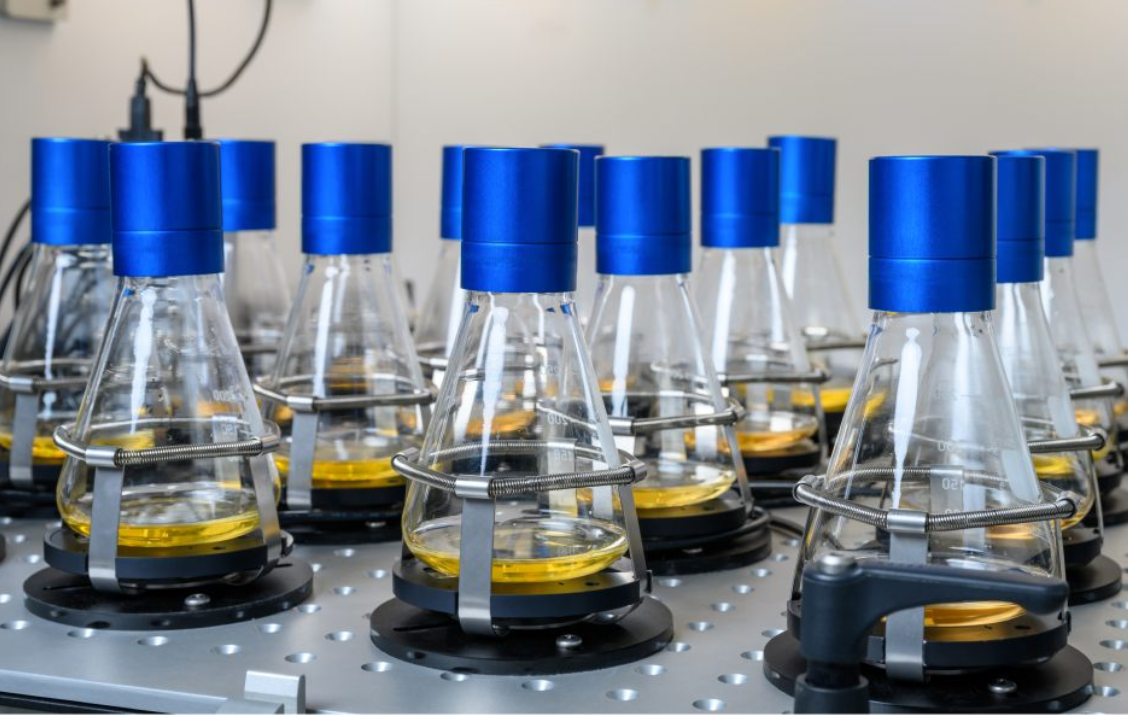

Sensors to Fit Your Vessel Type

For Shake Flasks

For Bioreactors

-

CELL GROWTH QUANTIFIER (CGQ)

Non-invasive, real-time monitoring of biomass in shake flasks and bottles via backscattered light detection.

-

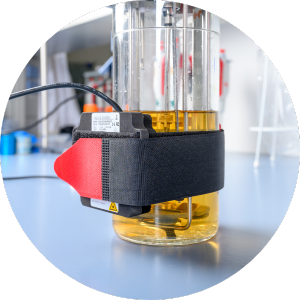

LIQUID INJECTION SYSTEM (LIS)

Automated and parallelized feeding of liquids in shake flasks.

-

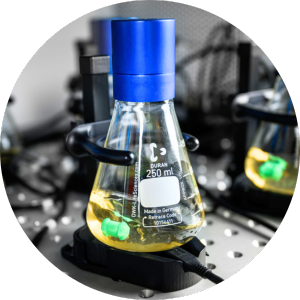

DISSOLVED OXYGEN (DO) SENSOR PILLS

First pill-based optical sensor for online dissolved oxygen (DO) monitoring in shake flasks.

Explore Our Applications

Biomass Monitoring

Biomass-Based Feeding

Dissolved Oxygen (DO) Monitoring

Microbial Screening

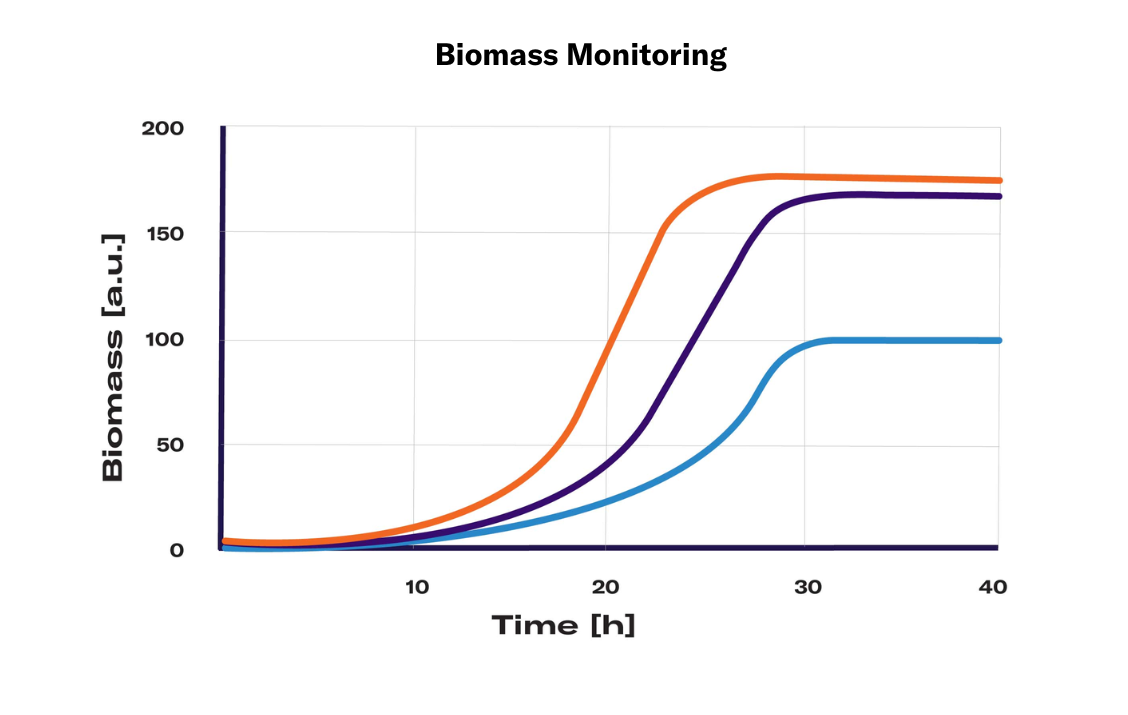

Biomass Monitoring

Biomass monitoring follows the development of cell concentration over time and characterizes the growth of the cultivated microorganism. Most microbial growth curves can be broken down into six distinctive growth phases.

Learn More

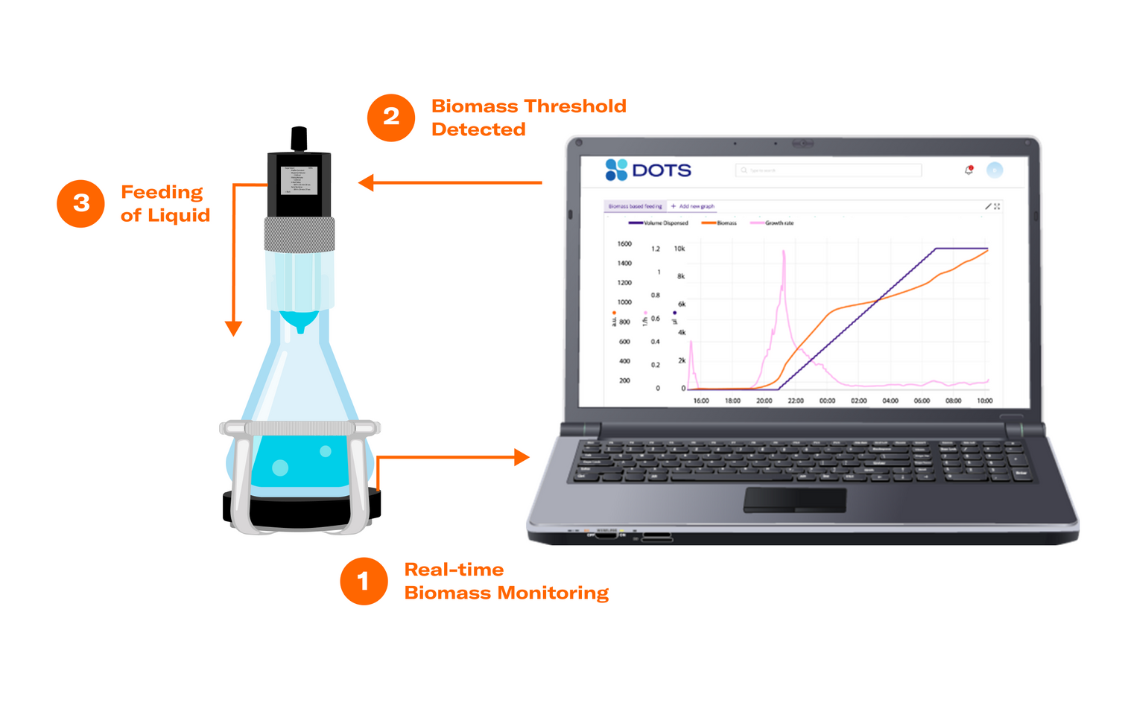

Biomass-Based Feeding In Shake Flasks

Automated biomass-based feeding allows an initiation of liquid injection that is dependent on cell growth and more fine-tuned to the needs of your cultivation.

Learn More

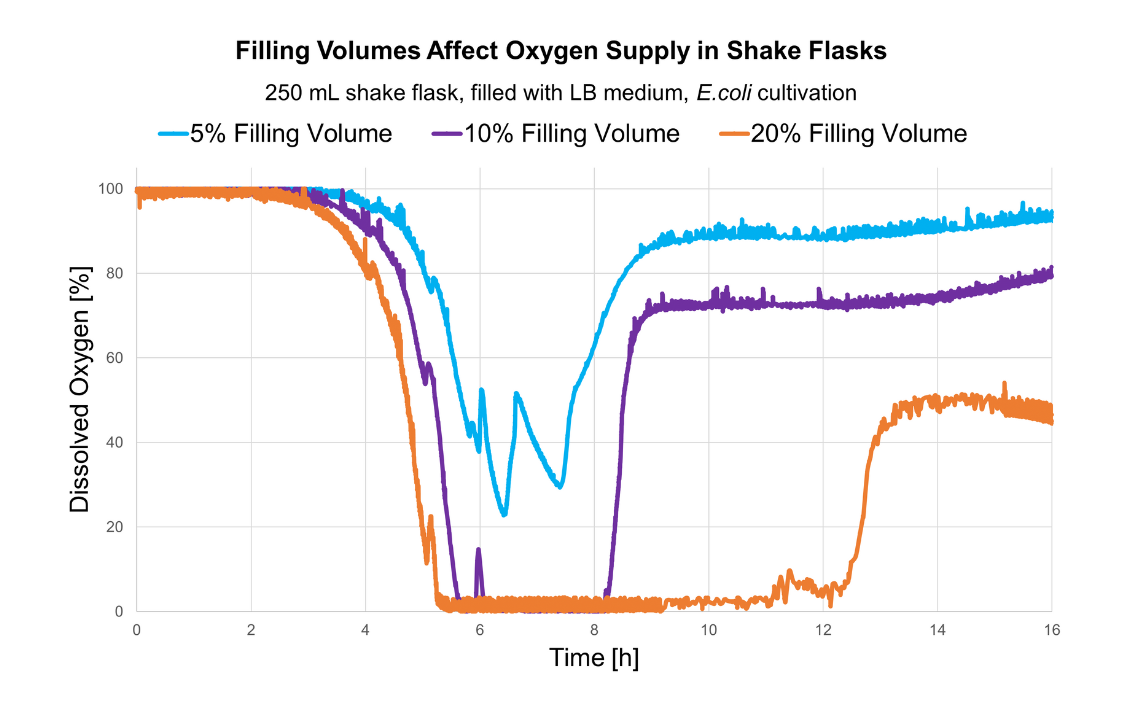

Dissolved Oxygen (DO) Monitoring

Oxygen is often considered a limiting factor in bioprocessing because if it falls below certain thresholds it can result in slowed metabolism, altered product formation, changed growth behavior, and in worst case, cell death.

Learn More

Microbial Screening In Shake Flasks

Improved scalability and cost-effectiveness make shake flasks an ideal choice for researchers conducting microbial screening assays.

Learn MoreLets chat!

Interested in one of our products or have questions about your bioprocessing?

Trusted by Industry and Academia Across the Globe

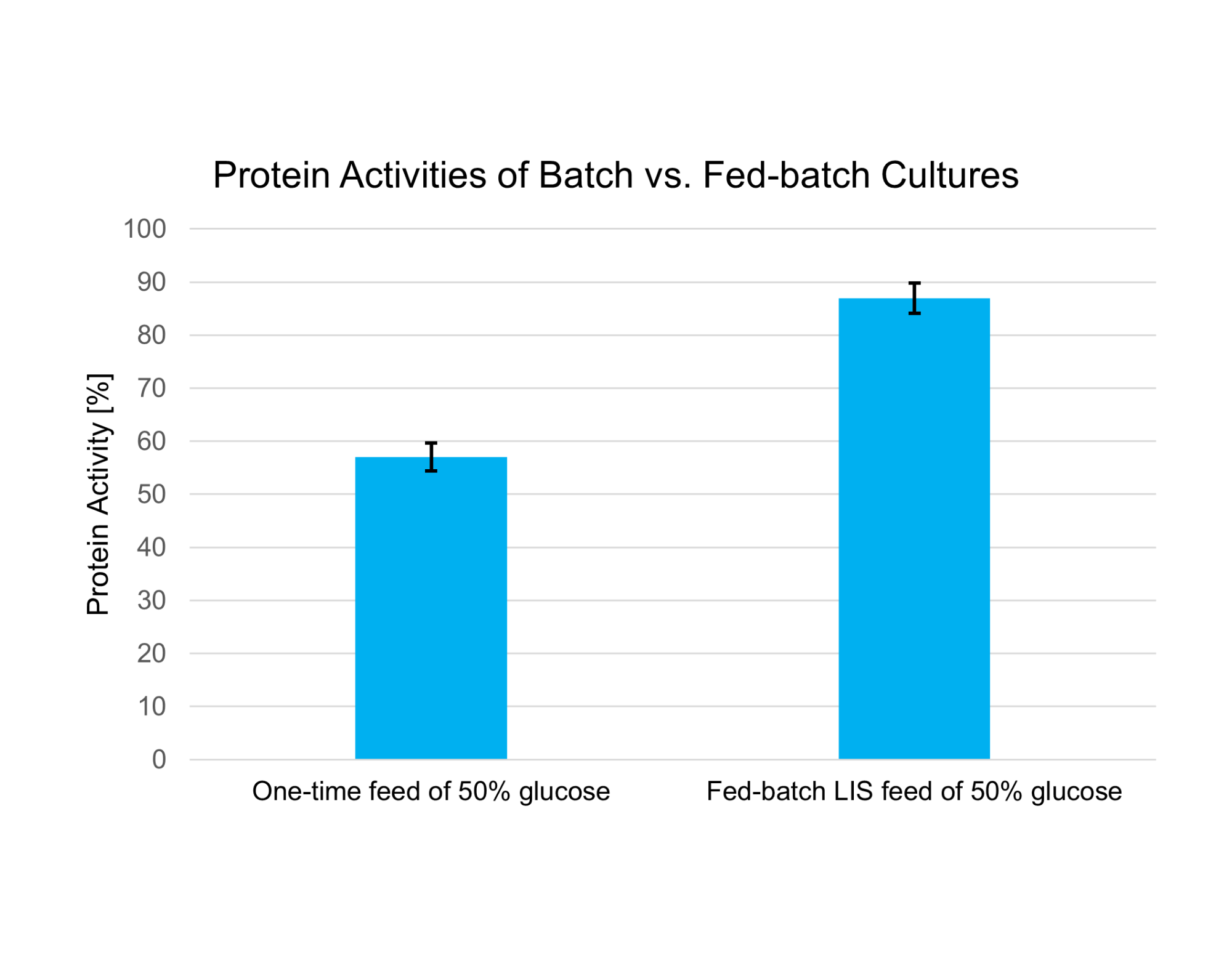

Fed-batch In Shake Flasks Increases Protein Yields

"By using the LIS, I can now continuously feed glucose in shake flasks. This improves the transferability of results from shake flask experiments to bioreactor runs."

Dr. Kambiz Morabbi Heravi (Project Manager Strain Engineering, Clariant)

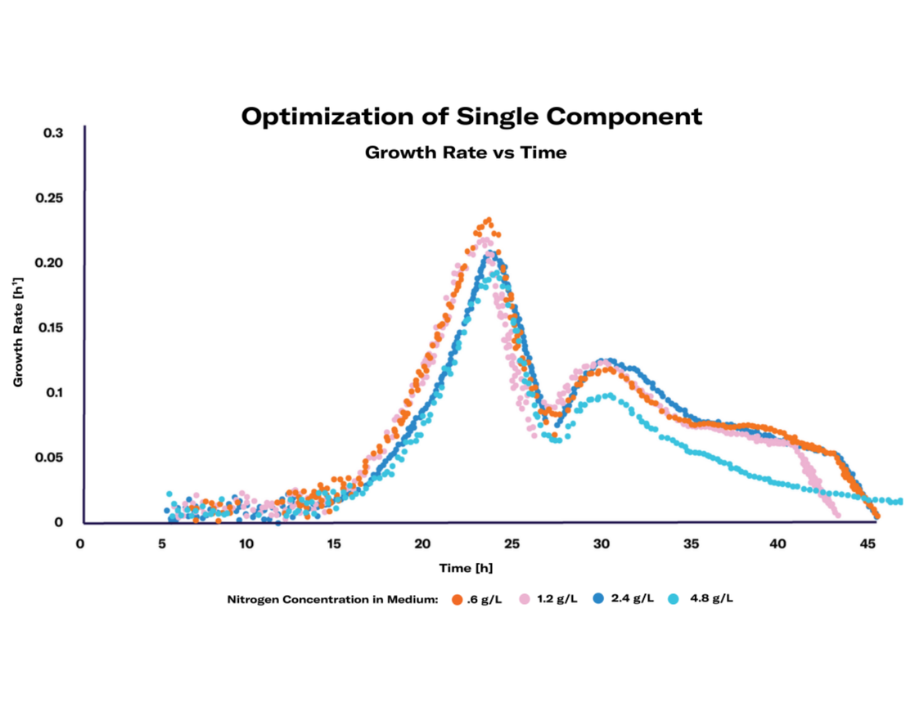

Growth Rate Monitoring Reveals Best Media Composition

"The real power of the CGQ is being able to sample at specific points of interest based on the continuous, high-resolution data. Otherwise, with manual sampling, it is just a shot in the dark. You never really know where in the growth curve the organism is."

- Raul Reveles (Bond Pet Foods)

CGQ BioR's Online Biomass Monitoring Aligns Well With Offline Data

.png?width=782&height=437&name=SBI-Success-Table-3-1%20(1).png)

"The CGQ BioR system provides precise growth curves with a very dense sampling interval, freeing my team for tasks with higher added value."

- Dipl. Ing. Andreas Hoffman (Technical University Dresden)

Stable Biomass Data Even Under Extreme Conditions

%20(1).png?width=1173&height=572&name=Kopie%20von%20Centrale%20Sup%C3%A9lec%20Image%20(7)%20(1).png)

"The CGQ BioR is well suited for monitoring biomass of cultivations with thermophilic organisms that require high temperatures and long fermentation times."

- Dipl. Ing. Robert Klausser (IBD Group, TU Wien)

Headline introducing the Process.

Lorem ipsum dolor sit amet, consectetur

adipiscing elit et am iatum.

Actionable benefit

This is a concise supporting benefit statement explaining how awesome the software is

Actionable benefit

This is a concise supporting benefit statement explaining how awesome the software is

Actionable benefit

This is a concise supporting benefit statement explaining how awesome the software is

.gif)