Data Spotlight

Biomass and Dissolved Oxygen Monitoring in CHO Cells for Enhanced Process Understanding

Background

Despite the increased availability of high-throughput small-scale bioreactor systems, the design and optimization of mammalian cell culture processes is still frequently performed in shake flasks. However, the measurement and control of critical process parameters, such as dissolved oxygen (DO) and particularly biomass concentration, can prove challenging. Ensuring sufficient oxygen supply is of upmost importance to guarantee adequate cell growth and comparability to larger-scale bioreactors. The measurement of biomass or viable cell density concentration is typically conducted manually, with daily sampling, but can be associated with perturbations at the cellular level and risk of contamination. To address these challenges of bioprocess monitoring, the DOTS Platform was evaluated by the Hamburg University of Technology for its ability to automatically monitor DO and biomass concentration in a Chinese hamster ovary (CHO) cell culture process. The generation of on-line data delivers insights into the cellular growth and state of the cell culture, enhancing process understanding.

Results

Materials & Methods

A CHO DP12 cell line was cultivated in 250 mL shake flasks (plain, vented cap, polycarbonate, Corning, USA) with 60 mL working volume and an initial viable cell concentration of 300,000 cells mL-1. The incubator was set to 37°C, 185 rpm (25 mm orbital diameter) and 5% CO2. The medium (TCX6D, Sartorius, Germany) was supplemented with 6 mM glutamine and 200 nM methotrexate. DO was measured using the DO Sensor Pills. The biomass concentration was determined by back-scattered light measurements using a LED emitting light with 940 nm.

Conclusion

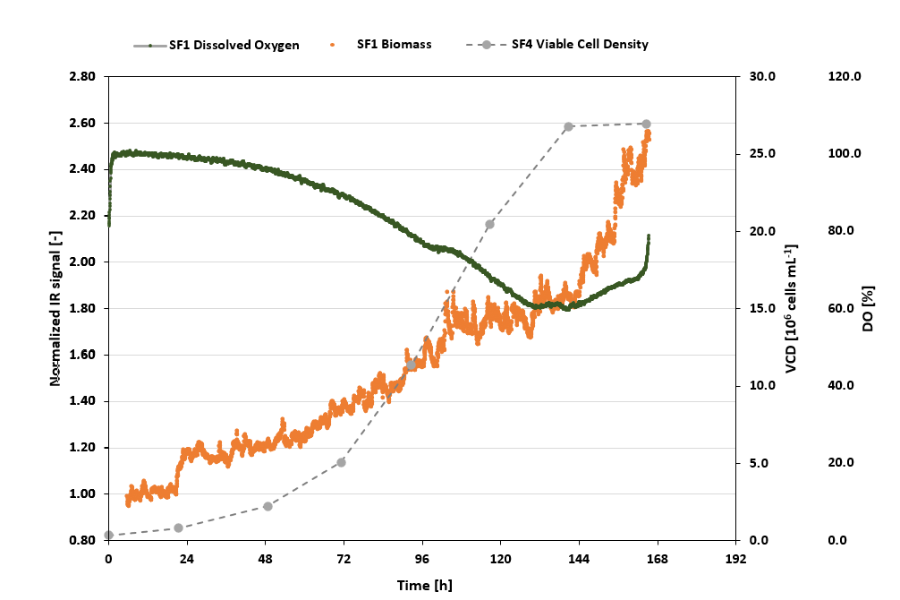

The obtained data show a reliable DO measurement (dark green marker) over the whole process time using the DO Sensor Pill. The changes in the DO progression after 96 h could be related to metabolic changes in the CHO metabolism as, for example, glutamine is typically consumed at this time point. The measurement of the backscattered light (orange marker) was sufficient. The signal increased throughout the cultivation time, as did the biomass during this period (grey marker, reference batch cultivation). Using further data analysis, the measured backscattered light signal could be used to determine an appropriate correlation and apply the backscattered light signal as an on-line process monitoring tool. Overall, it has been shown that on-line DO and biomass can be measured simultaneously using the sbi Multiparameter Sensor (MPS) system, enabling the use of standard shake flasks and eliminated the need for daily manual sampling.

Have questions about your application?

Let’s work together to find a solution that works best for you.

From Estimation To High-Resolution Growth Curves

Customer Success Stories

.png)

-Kitana Manivone Kaiphanliam (Washington State University)