Lack of Control

- Lacks bioreactor control options for e.g., pH control or fed-batch

- Leads to inconsistencies in scale-up between shake flask and bioreactors

Open a whole new world of bioprocess development when you use LIS to perform automatic feeding in shake flasks. Simply assemble the components, define the experiment parameters, fill the cartridge with the feeding liquid, and start feeding.

Key Features

Benefits

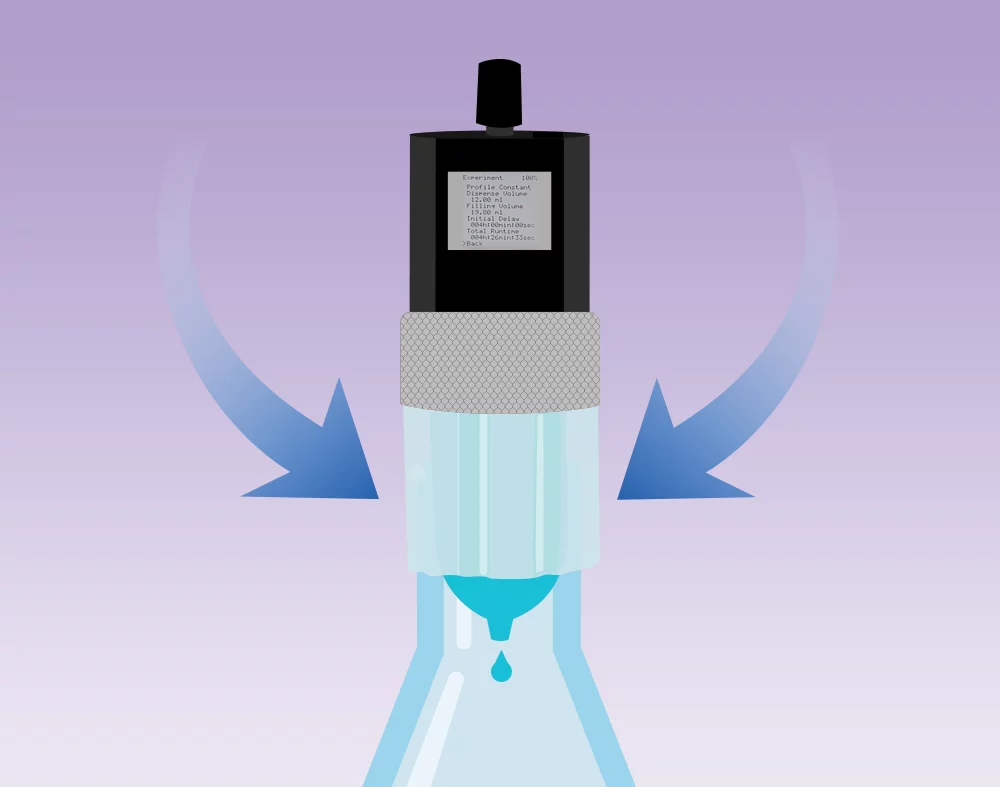

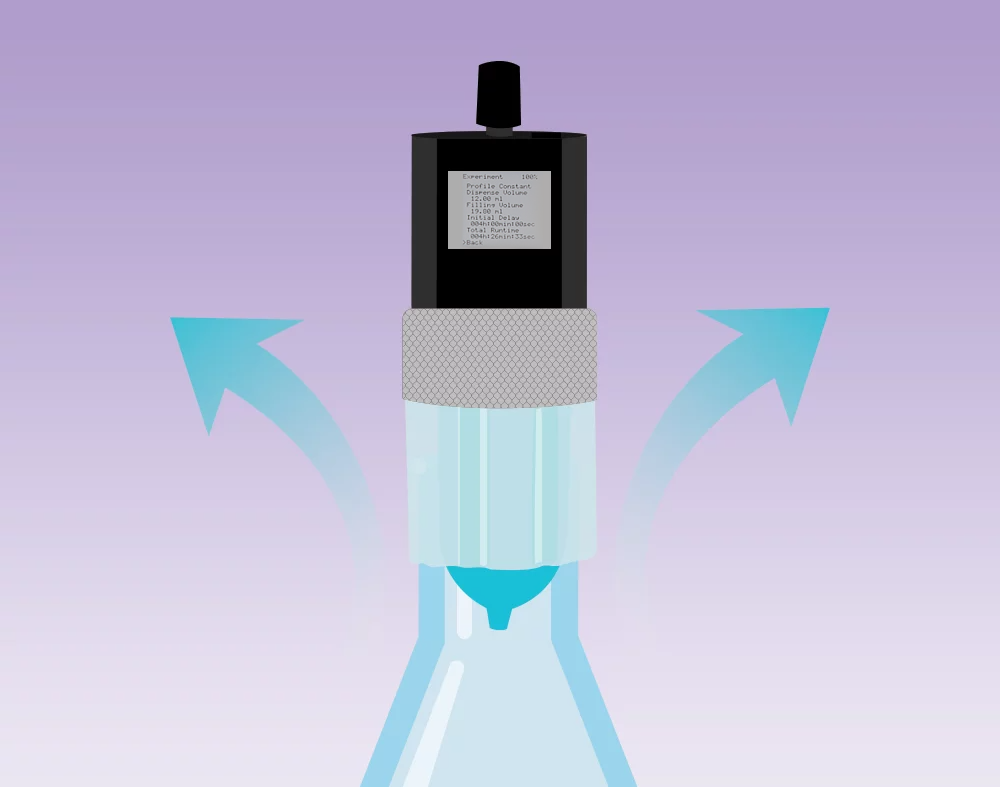

In order to dispense a defined amount of liquid from the cartridge, the drive pumps air through a sterile filter into the cartridge according to the feeding profile.

After the dispense step, the drive rebuilds negative pressure to keep the remaining liquid in the cartridge.

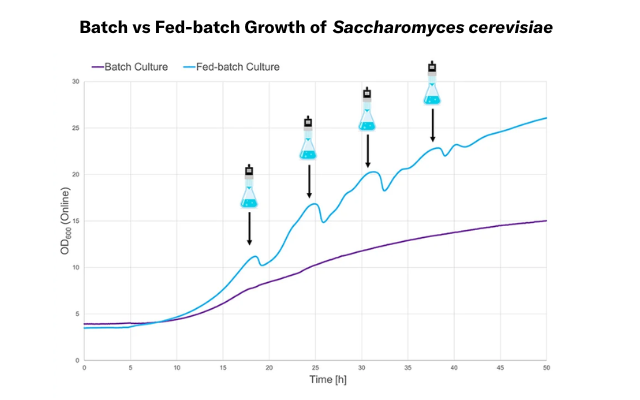

With LIS, typical bioreactor processes, like fed-batch cultivations, can be recreated in shake flasks. Fed-batch cultures support the growth of S. cerevisiae on potato waste because the concentration of growth inhibitors in the medium can be controlled. With the LIS, these process conditions could be imitated on a shake flask level.

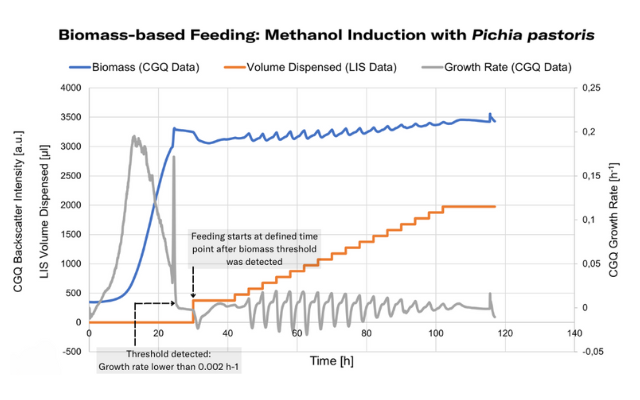

Enable feedback-controlled feeding in your shake flask experiments when you connect LIS with reliable biomass monitoring sensors such as the Cell Growth Quantifier (CGQ), or Multiparameter Sensor (MPS), and the DOTS Software. Biomass-based feeding can be used to initiate methanol induction at the optimal time - once cell growth on the primary substrate (glycerol) is complete and sufficient biomass was generated, indicated by a reduction in growth rate.

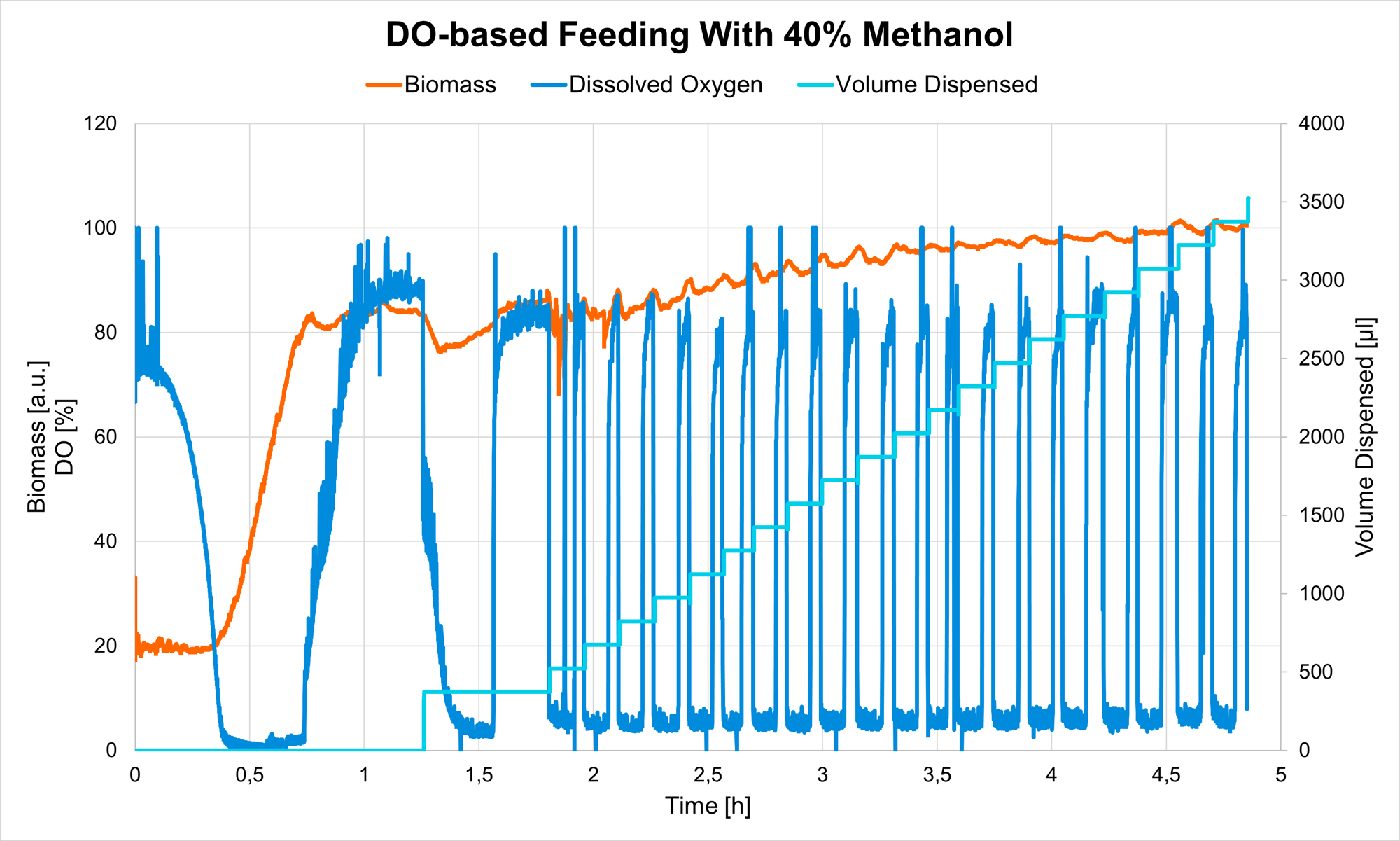

With a DOTS-integrated controller, the methanol feed (carried out with the Liquid Injection System) was adjusted to start repeatedly, always when the DO level, monitored by DO Sensor Pills, reached a preset threshold. By using this feature, methanol was always fed as soon as the cells recovered from the previous shot, enabling ideal cell viability, while keeping promotor activity constant. Biomass was monitored additionally, with the Multiparameter Sensor (MPS).

The drive is a programmable miniature pump that controls when and how much liquid is fed from the cartridge into the flask.

The cartridge is a pre-sterilized, ready-to-use container that fits on top of the shake flask. It can be filled with up to 25 mL of any type of liquid and acts as a reservoir during the feeding experiment.

The DOTS Software allows you to wirelessly control and monitor your feeding experiments. Create individual feeding profiles, define feeding parameters, and monitor the expensed liquid volume over time. By combining other DOTS integrated sensors, parameter-based feeding can be realized.

Use the interconnectivity of sensors (CGQ) and actuators (LIS) within the new DOTS Software to enable feedback controlled feeding in your shake flask experiments. Set up your injection strategy based on your biomass threshold or growth rate and start feeding based on the specific needs of your culture.

The LIS is designed to fit any 38 mm straight neck Erlenmeyer shake flask.

LIS has been successfully tested with a broad variety of liquids. Our team of application scientists will work with you to ensure that the liquid and concentration needed for your particular application can be used with our feeding system.

Sugars

Alcohols

Glycerol

Acids, bases, and inductors (e.g., IPTG)

Antifoam

The LIS is designed to fit any 38 mm straight neck Erlenmeyer shake flask.

LIS has been successfully tested with a broad variety of liquids. Our team of application scientists will work with you to ensure that the liquid and concentration needed for your particular application can be used with our feeding system.

Sugars

Alcohols

Glycerol

Acids, bases, and inductors (e.g., IPTG)

Antifoam

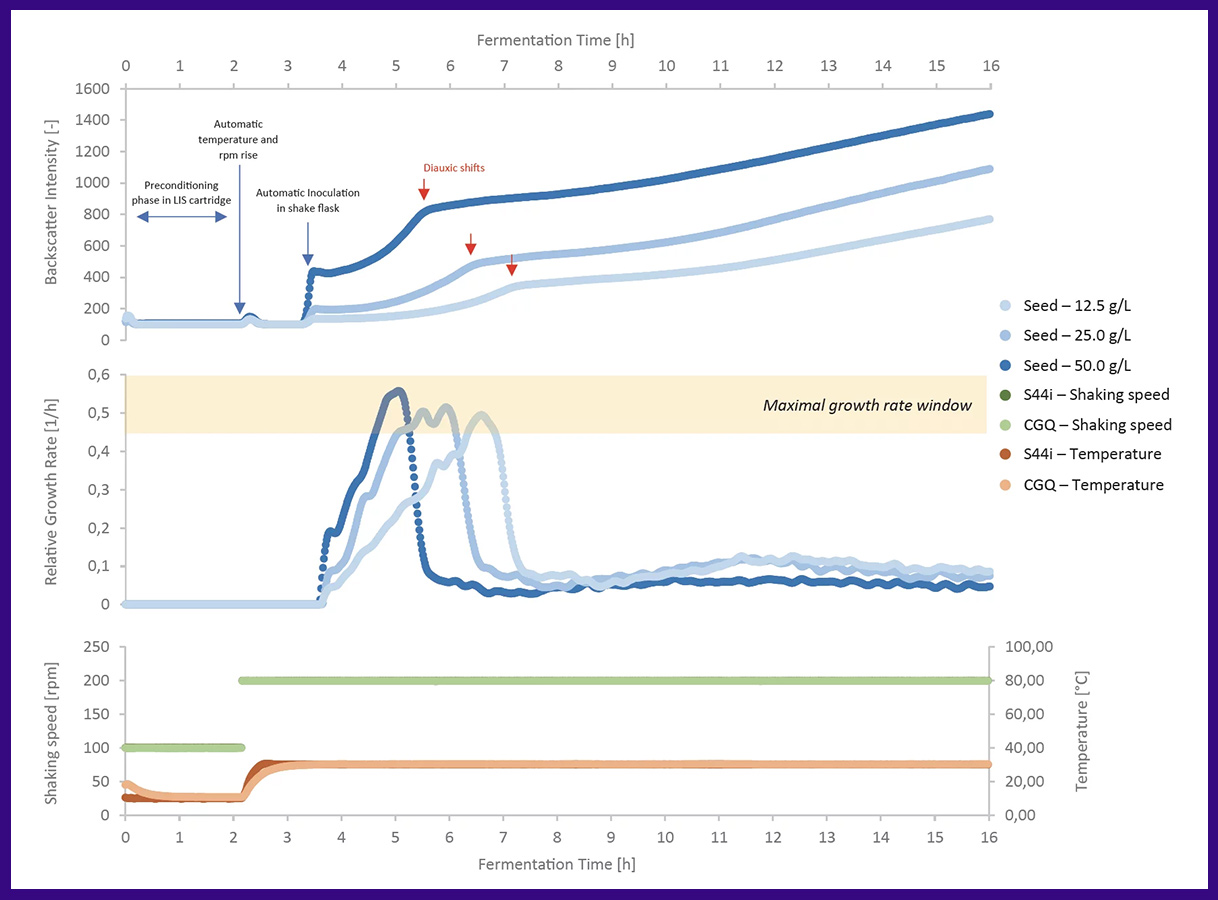

This application note illustrates the use of LIS in conjunction with the yeast S. cerevisiae to optimize bioreactor inoculum in shake flasks. After a period of preconditioning, the LIS automatically injects different seed biomass concentrations into a shake flask containing fresh YEPD. Cell growth is monitored in real-time to assess the reproducibility of environmental and growth phase conditions.

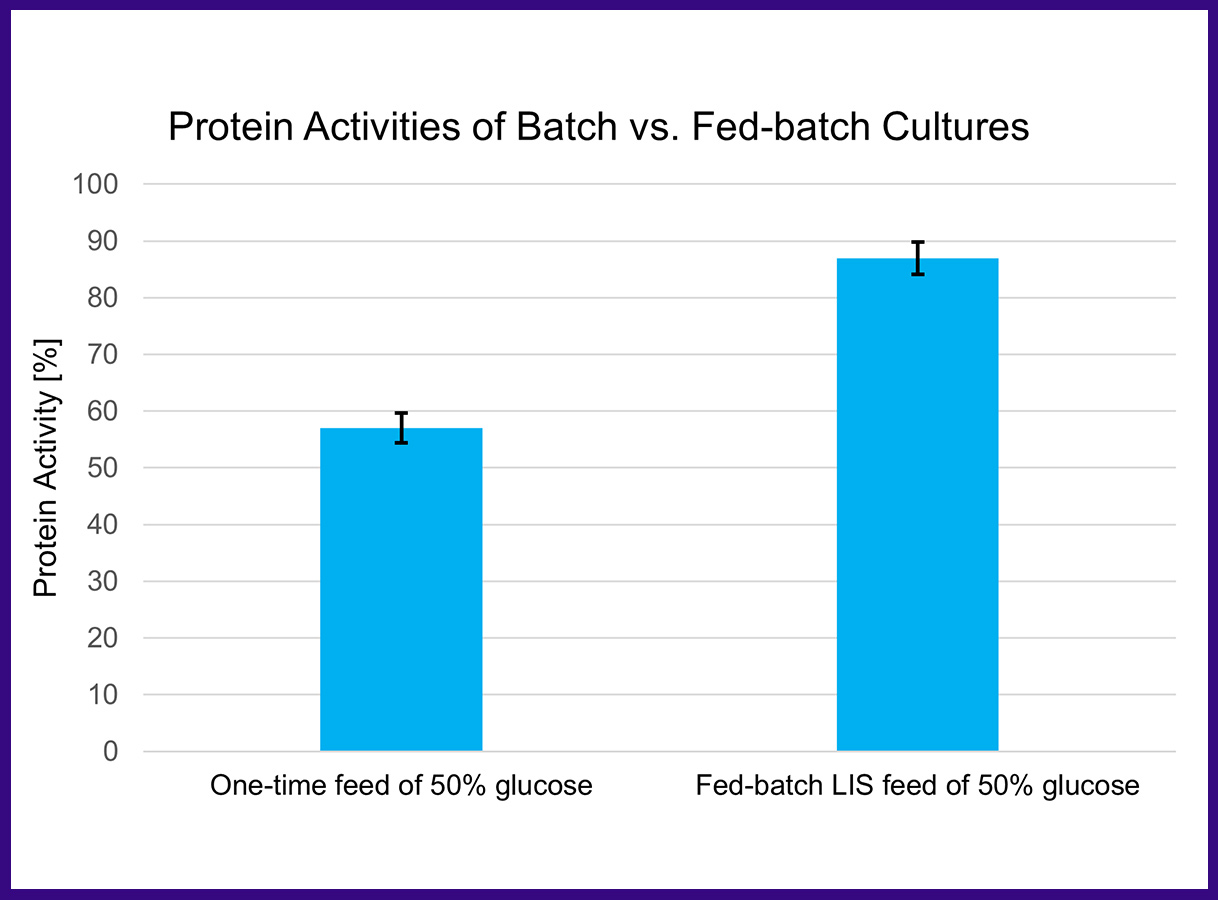

The batch condition has a great impact on the cell's metabolism which overshadows the strain's characteristic protein production behavior. A LIS facilitated fed-batch process showed a significant increase (30%) in active protein yields, compared to a batch process and is better suited to screen for the best production strain.