Data Spotlight

Online Monitoring and Automated Feeding for Early Process Characterization

Background

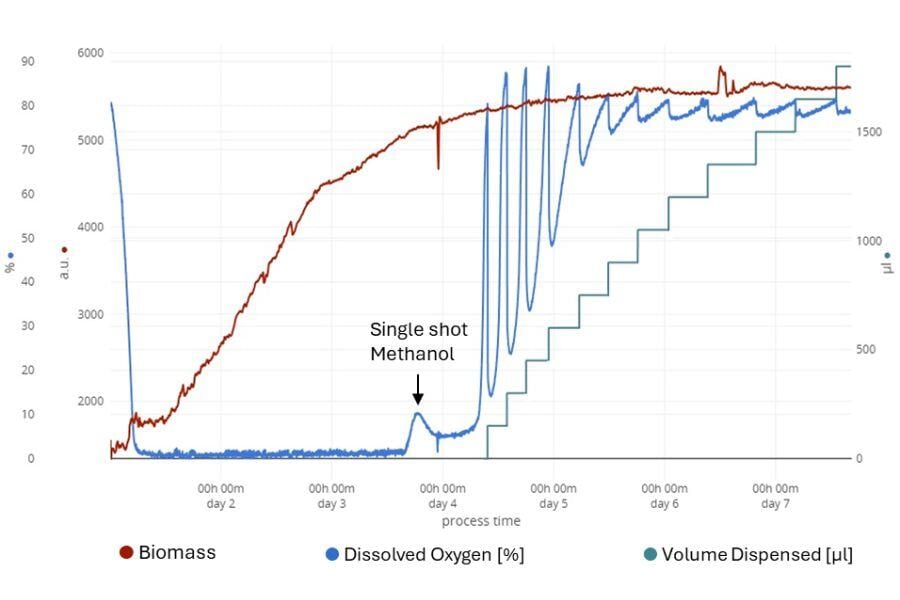

The cultivation of Pichia pastoris using methanol as a carbon source requires precise feeding strategies to balance growth and productivity while minimizing toxicity and contamination risks. During this experiment, the Multiparameter Sensor (MPS) and Dissolved Oxygen (DO) Sensor Pill were used to automate methanol feeding dynamically, with DO serving as a reliable metabolic marker.

This innovative approach aimed to replace manual feeding with automated systems, the Liquid Injection System (LIS) for precise methanol addition. The study demonstrated the potential of online monitoring to enhance data collection, reduce process interruptions, and accelerate the optimization of Pichia fermentation processes, laying the groundwork for scalable, efficient bioprocessing applications.

Results

Materials & Methods

Experimental Setup:

-

- Culture Conditions: 250 mL shake flask with 25 mL Pichia culture, shaken in an incubator at 28°C and 250 rpm (ø 25 mm).

- After the batch phase, where biomass was generated by growth on glycerol, MeOH feeding was started.

- Methanol Feeding Protocol:

- Initial waiting time of 57 hours followed by a 750 µL shot of 20% methanol.

- After an additional waiting time of 7 hours, DO-based feeding of 20% methanol was started.

- Feeding was triggered when dissolved oxygen levels rose above 80%.

- Automation: Feeding steps were conducted automatically using the Liquid Injection System (LIS).

Conclusion

During the experiment, the technical functionality of the system was successfully evaluated, resulting in several key insights:

- Improved Efficiency: Online monitoring eliminated the need for manual sampling and feeding (which would have been required 3-4 times daily).

- Enhanced Data Collection: Automated systems enabled continuous data collection compared to only 4 manual data points per day, ensuring a clear understanding of oxygen content during cultivation.

- Reduced Interruptions: Automation minimized process interruptions, reducing negative impacts on growth and contamination risks.

- Accelerated Optimization: Online monitoring and automatic feeding allowed for quicker process characterization and earlier optimization of Pichia.

Have questions about your application?

Let’s work together to find a solution that works best for you.

From Estimation To High-Resolution Growth Curves

Customer Success Stories

.png)

-Kitana Manivone Kaiphanliam (Washington State University)